Duy Khanh Engineering Co.,Ltd is one of the leading companies in Ho Chi Minh City in the field of precision mechanical processing. With more than 34 years of experience, we hope to bring customers customized products with high quality, technical consulting services, thoughtful after-sales, reasonable costs.

Our products are divided into the following main groups:

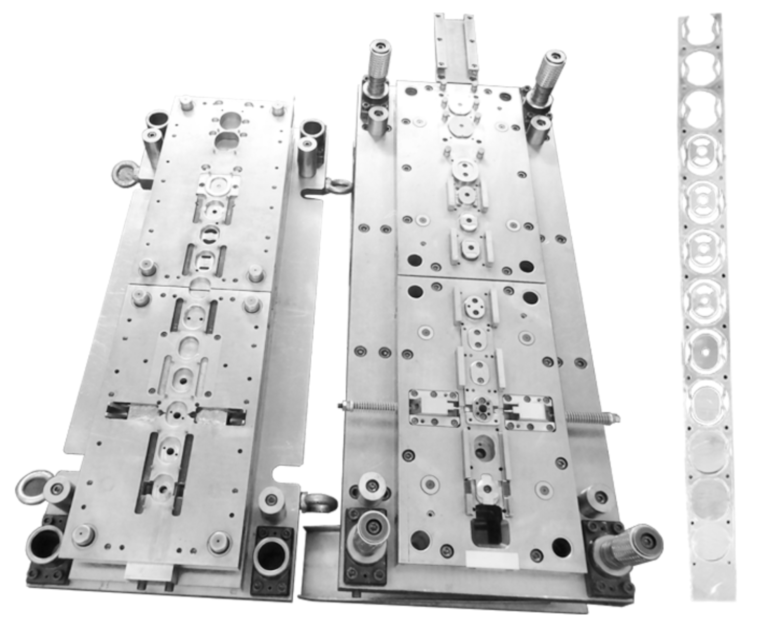

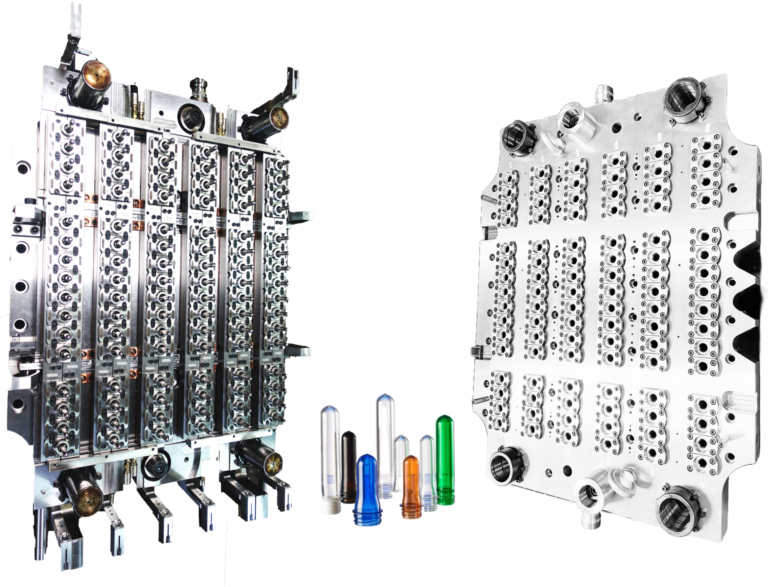

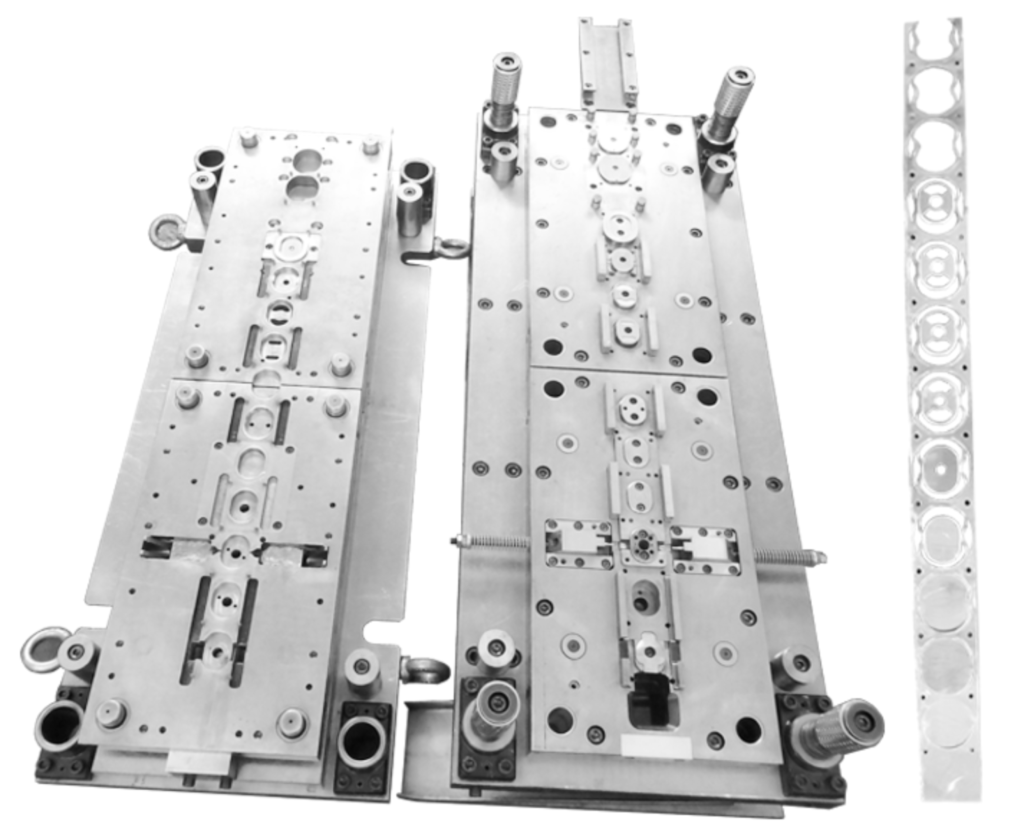

1- Design and manufacture of molds of all kinds for plastic industry, metal stamping, pressure casting. Especially continuous stamping dies and transfer stamping dies for sheet metal products and precision plastic injection molds for plastic & rubber products. In particular, Duy Khanh is a Vietnamese unit that successfully manufactures and assembles PET preform mold – 96 CAV.

2- Design and manufacture of tools, jigs and special-use equipment at the request of customers.

3- Precision mechanical machining by CNC machine, EDM, Wire – Cut parts, assembled according to customer’s drawings. In particular, we have a shaft production line, supplying FDI companies in Vietnam (Japan, Italy, Korea,…).

4- Especially, the production of components and machine parts from metal powder by sintering powder technology. We are proud to be the first Vietnamese unit to produce Powder Metallurgy products in Vietnam.

PRODUCT DETAILS

Molds

1. Designing and manufacturing: o Molds: • Injection molds, blow molds for plastic parts, PET pre-form molds. • Forming, progressive, and transfer stamping dies for sheet metal. • Die-casting molds. • Forming molds for rubber products. o Customized machinery, tooling & fixture.

| Product Name | Molds |

Parts – Precision components

2. Powder metallurgy machine parts.

| Product Name | Parts – Precision components |

Machinery parts by Metal Powder Sintering Technology.

3. Precision CNC machining per customer’s drawings.

| Product Name | Machinery parts by Metal Powder Sintering Technology. |